Energy Opticon is, with the software Energy Optima 3, one of the largest suppliers of forecasting and economical computer optimization for energy production. Energy Optima 3 has been on the market since 1992 and our software has been developed and fine-tuned by our staff in collaboration with our customers in a variety of new releases of the software.

Energy Optima 3 is a modular IT solution for:

-

Accurate forecasts

-

Economical optimization of energy production

-

Trading on the energy market (eg. electricity and gas)

-

Decision support for production planning

All modules are standard software and the modular structure allows Energy Opticon to deliver individual solutions according to the specific customer’s demands. This means that each part of the program works, and can be purchased separately, without any limitation on communication between the modules. Access to modules and functions are controlled via users and password.

The software has been in operation at customer’s sites (in different releases) since over 22 years. By continuous and by constantly adjusting and refining along our customers' requests together with the usage of Microsoft.net framework, we already created the environment for a safe and successful future for at least the next 10-15 years.

Energy Optima 3 is supplied either as a data-based client / server system that uses Windows as a platform or as a service from Energy Opticon over the Internet.

USER benefits WITH ENERGY OPTIMA 3

Without computer optimized tools for the energy production, it is very difficult to always operate economically optimal. In order to minimize production costs, a mathematical model of the energy system is needed. It is very difficult to combine continuous and binary variables in minimizing costs, and the human factor increases risks for errors.

Management & Production Planners

- Reduce costs and increase profits: By using Energy Optima 3, the variable production costs can usually be reduced by 2-10 %. At the same time, with optimization of the energy trading, the profit is also maximized. This could mean hundred thousands of EUR each year.

- Increase quality, with full transparency: By using a tested and trimmed system for production optimizations, the management can rely on the quality of the planning. It is all clear which parameters, limitations, contracts and other influencing factors are taken into consideration.

- Easy reporting: Energy Optima 3 provides a wide range of possibilities to present data and to keep information flowing. The management is informed with individual reports including main information or key indicators. The follow-up can be used to motivate staff by increasing key indicators.

- Save time: through less manual and complex calculations, you can free up time for other important tasks. Calculate differences between actual and optimal operation, to evaluate the quality of the operation and analyze which optimization potential is left.

- Decision support: Energy Optima 3’s production plans are used for unit steering, trading, planning and evaluations. The planner has transparent and qualitative information to make decisions from the intraday trading up to long term project evaluations (return of investment).

- Facilitate planning of: Optimal production plans for each unit, optimal trading volume and strategies, evaluation of long-term strategies and projects.

Energy Trading

Trading and production are strongly correlated. Calculating production plans is depending on trading possibilities as well as the trading portfolio is depending on the production amounts. A close work relation between the production planning and the trading processes is key factor for a successful business in all departments.

- Common work basis: Energy Optima 3 delivers results for each department in energy companies and is common base for the traders and the production planners. Trading volumes are optimized at the same time as production plan considering all influencing market prices and unit limitations/factors.

- Confirmation of production plans and trading volumes: The results from Energy Optima 3 can or must be confirmed. By confirmation the system keeps information for later optimizations and it is sent out automatically in the required formats.

- Automatic Intraday Trading: Optimized production plans can be fed directly into the autoTRADER program for automatic AI trading on the Energy Trading Market.

Dispatch/operational level

- Decision support: Energy Optima 3 delivers results for an optimal operation of units

- Explanation: Energy Optima 3 allows quick analyses to explain production plans

- Economical awareness in the whole team: Raise the awareness for economical thinking in all aspects of the operation of the plant among the staff. The system can be used to strengthen new ways of thinking and new knowledge about different factors that affect the economy in the energy production.

User-friendlINESS

Energy Optima 3 is from the start constructed to be user-friendly. It is well modelled, reflecting reality in a comfortable logical environment with graphs, tables and other reports. Therefore, it is easy to work with and to set into practical operation. These features are important in order for an optimization program to be used in plant operation.

The latest technology on the market

Energy Optima 3 is a very modern product of the latest technology in its field. It benefits great features like:

-

The world-leading High-Speed Optimization function

-

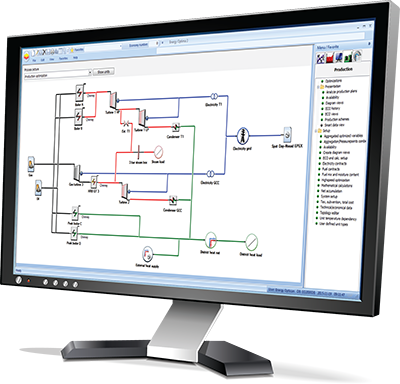

The Topology Editor – a highly advanced graphical program for energy system modelling

-

Advanced economical follow-up with analyses of economical deviations between actual and optimal operation

-

Business Intelligence with advanced functions for specially designed reports and for standardized import/export interfaces.

- Optimization of different types of balance power including price forecasts

Furthermore, the Energy Opticon team is continuously in the business of developing the program, and it is continuously being updated